Category List

Contact Us

Mob/Wechat/WhatsApp:

E-mail:

Address:

513 Guangzhou North Road, Jiaozhou City, Qingdao, Shandong, China

30Tons Full Continuous waste tire pyrolysis plant

Category:

Continuous Tire Pyrolysis Plant

Continuous waste tire pyrolysis reactor

One billion used tires are produced every year,and the recycling of tires is a problem that needs to be faced all over the world.

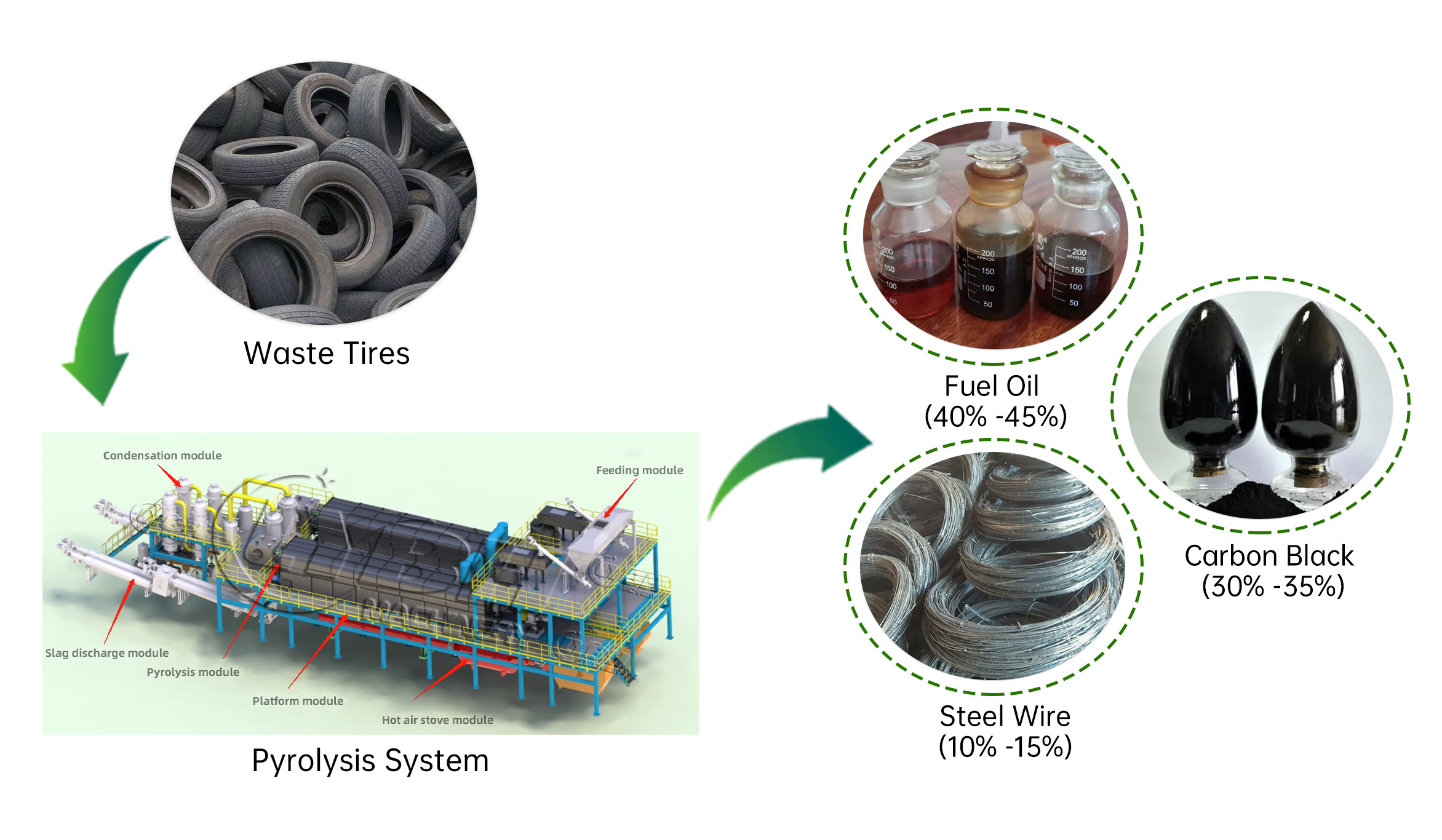

Waste tire pyrolysis process is the main way to solve the problem of waste tire reuse:

Pyrolysis treatment has no pollution emissions,and can recover fuel oil and carbon black,steel wire,which is conducive to environmental protection and resource utilization,and has high economic value,and is considered to be one of the best ways to deal with waste tires at present.

About us:

Our company mainly produces fully automatic waste tire shredding and pyrolysising production lines, waste rubber pyrolysis equipment, waste plastic pyrolysis machine, and oil sludge pyrolysis machine.At the same time, our company integrates front-end processing, mid-range cracking machine, and back-end carbon black grinding and granulation,The entire production chain has achieved low energy consumption、fully intelligent、zero emission、zero pollution and zero residue,Realizing the reuse of green and environmentally friendly resources by recycling and pyrolysising waste tires.

Machine Description:

This equipment can complete new type of continuous pyrolysis plant for environmentally friendly processing of waste tires.With crushing processing,continuous pyrolysis,carbon black treatment,gas recovery,flammable gas reuse,waste iron wire treatment,etc, and the whole process of scale,automation,large quantities of various specification of waste tires can be processed.

1.Break the waste tires into small pieces and remove most of the steel wires by magnetic separation to obtain waste tires of suitable size.

2.The tire block is continuously fed into the pyrolysis through the feeder,and the pyrolysis reaction is fed.The heating system controls and heats the cracker,so that the materials in the pyrolyzer undergo pyrolysis reaction at a set temperature.

3.The raw materials are sent from the feeding device to the transition silo,and are continuously sent to the heater through the feeding device.After low-temperature pyrolysis reaction,products such as fuel oil,non-condensable combustible gas and solid fuel are obtained.

| Name | Unit | Continuous type waste tire pyrolysis plant | ||||||

| Equipment type | BH-SC30 | |||||||

| 24h capacity | T | 30 | ||||||

| Reactor size | mm | 1400*20000 | ||||||

| Reactor material | 12Cr1Mov/Q345R/Q235R | |||||||

| Floor area | m² | 40*12*9 | ||||||

| Feed modes | Feed conveyor | |||||||

| Labor | 2-3 people | |||||||

Keywords: Waste Tire Pyrolysis Plant | Recycling machine | Carbon Black Processing Machine

Related Products

Related Messages

Qingdao Longyuan Baihong Machinery Equipment Co., Ltd.

Mob: +86 15854201728(Helen)

E-mail: info@qdlybh.com

Add: 513 Guangzhou North Road, Jiaozhou City, Qingdao,Shandong Province,China

Customer Message

Copyright © 2023 Longyuan Baihong SEO Business license