Category List

Contact Us

Mob/Wechat/WhatsApp:

E-mail:

Address:

513 Guangzhou North Road, Jiaozhou City, Qingdao, Shandong, China

Best design rubber block production from waste tire shredder recycling machine

Category:

Waste Tire Recycling Machine

Best design rubber block production from waste tire shredder recycling machine

Recycling machine introduction:

Due to the development of the automotive industry, the number of waste tires is also increasing. How to effectively handle these waste tires, such as the waste tire crushing production line/grinding production line, which converts waste tire into useful raw materials

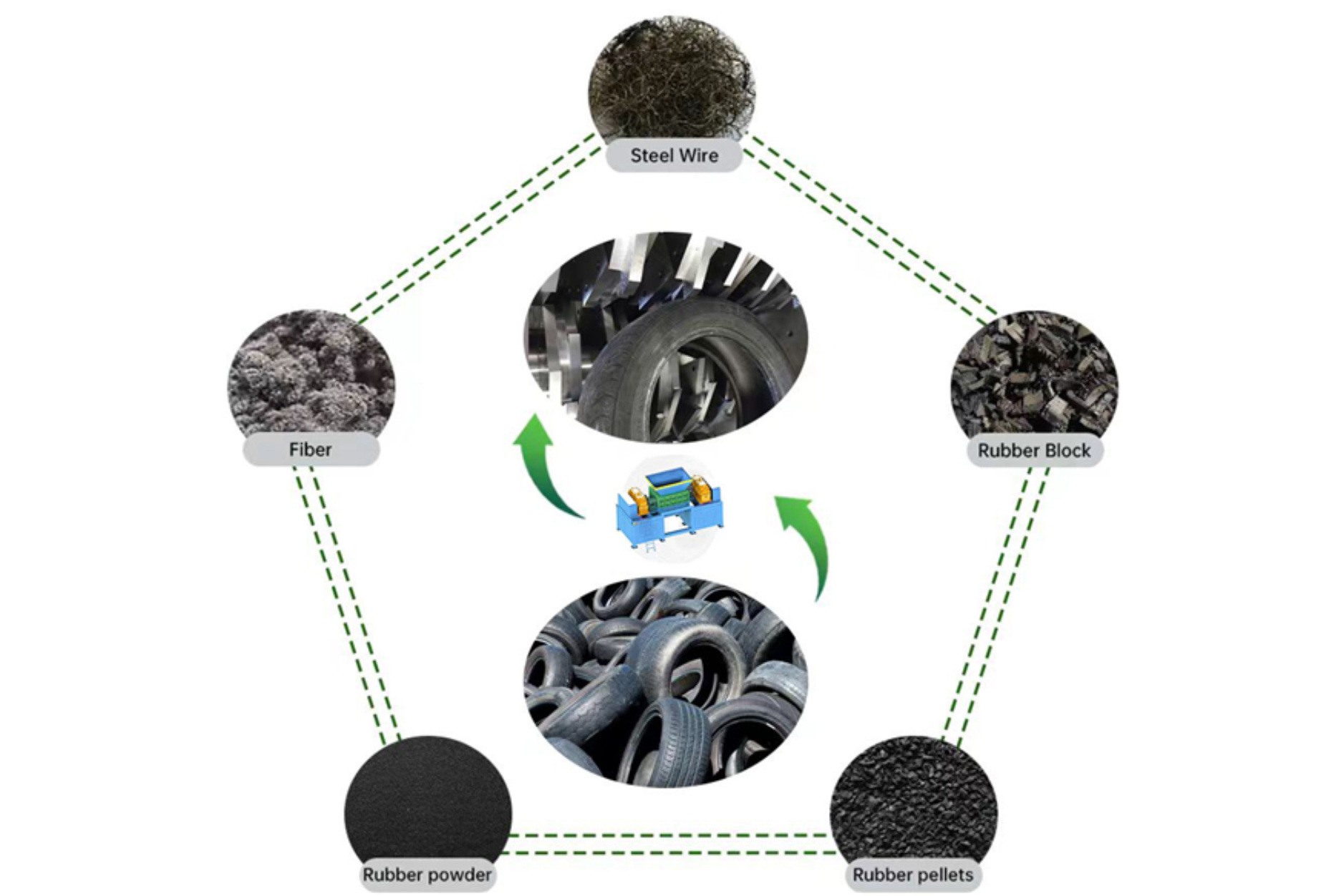

The tire crushing and grinding production line is mainly used to dispose of waste tires by shredder, separating steel wire, crushing, and separating fiber, so as to achieve regeneration of waste tire

1. The benefits of tire recycling for environmental protection

Waste tire can be converted into reusable raw materials through recycling and grinding production lines, solving environmental pollution problems

2. Economic benefits of tire recycling

The raw materials from crush and recycled waste tires can be used to manufacture new tires, road materials, etc., achieving resource recycling and promoting economic development.

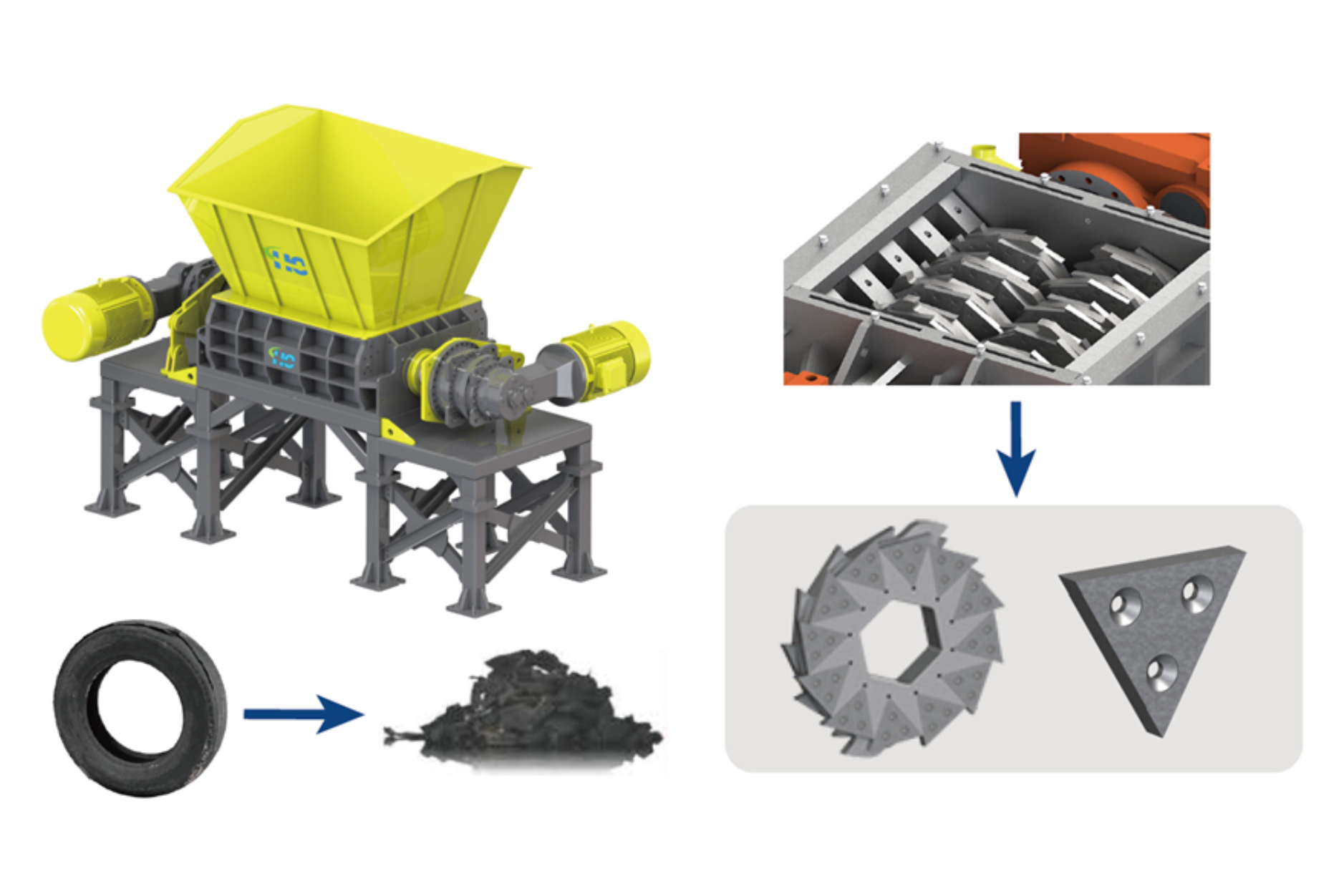

3. Production process of recycling machine

Waste tires are separated from steel wires by wire drawing machine, which crushes waste tire into smaller rubber blocks. The steel wire separator the rubber blocks and vibrates screening. The fiber separator and magnetic separator separate the fibers and steel wires from the tire powder

Rubber shredder parameter

| Name | 610 type | 710 type | 810 type | |

| No | Component | Technical | Technical | Technical |

| 1 | Helical roller | 610mm *1000mm | 710mm*1000mm | 810mm*1200mm |

| 2 | Straight tooth roller | 510mm*1000mm | 610mm*1000mm | 710mm*1200mm |

| 3 | 20 mesh Rubber powder | 1000-1200kg | 1200-1500kg | 1500-2000kg |

| 4 | Dimension | 5400mm*2000mm*1400mm | 6200mm*2260mm*1700mm | 6400mm*2700mm*2400mm |

| 5 | Motor power | Y2-325M2-6 -200-220kw | Y2-355m2-6 -250kw-280kw | Y2-400m2-8 -315kw |

| Auxiliary machine | ||||

| No | Component | Total power | Total power | Total power |

| 1 | main vibrating screen | 29kw | 31kw | 48kw |

| 2 | secondary vibrating screen | |||

| 3 | 9000 magnetic separator | |||

| 4 | rubber powder feeding belt | |||

| 5 | anti-tying belt machine | |||

| 6 | 12000 magnetic separator | |||

| 7 | rubber powder collector | |||

Our company

Qingdao Longyuan Baihong Mechanical Equipment Co., Ltd. is located in Qingdao, Shandong Province. The company has taken the responsibility of recycling waste resources and creating a green ecological environment. In the continuous technological breakthroughs, our company andQingdao University of Science and Technology have jointly established a laboratory and jointly developed waste tire pyrolysis carbon black equipment realized the intelligentization of Industry 4.0, and the factory changed from a large number of manual operations to automated production. Our company mainly produces fully continuous waste tires, waste rubber, waste plastics, and sludge pyrolysis plant. At the same time, our company integrates front-end treatment, MID-end pyrolysis plant and back-end carbon black grinding and granulation.

Keywords: Waste Tire Pyrolysis Plant | Recycling machine | Carbon Black Processing Machine

Related Products

Related Messages

Qingdao Longyuan Baihong Machinery Equipment Co., Ltd.

Mob: +86 15854201728(Helen)

E-mail: info@qdlybh.com

Add: 513 Guangzhou North Road, Jiaozhou City, Qingdao,Shandong Province,China

Customer Message

Copyright © 2023 Longyuan Baihong SEO Business license