Category List

Contact Us

Mob/Wechat/WhatsApp:

E-mail:

Address:

513 Guangzhou North Road, Jiaozhou City, Qingdao, Shandong, China

Waste Tire Full Continuous Pyrolysis Plant

Category:

Continuous Tire Pyrolysis Plant

Machine description:

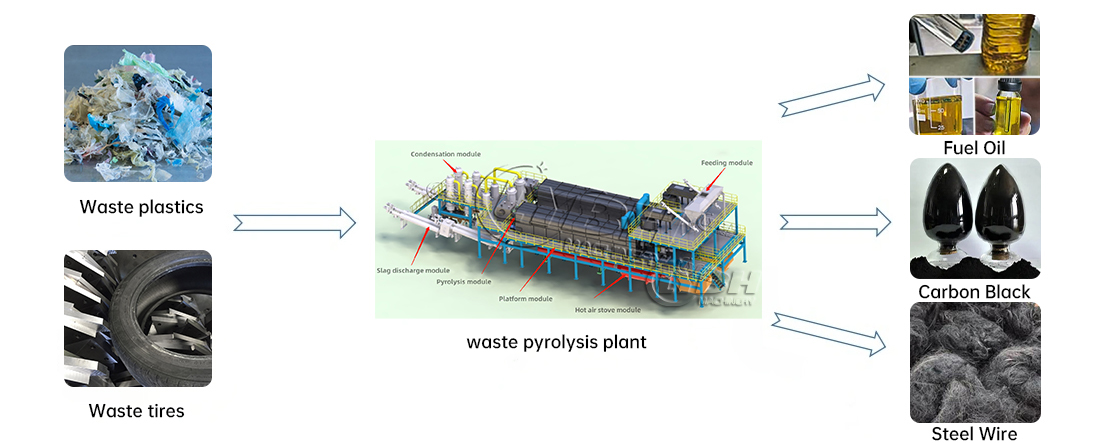

Continuous pyrolysis equipment will pyrolysis waste tires or tire rubber blocks, and undergo rapid pyrolysis reactions under vacuum conditions at temperatures of 450-550P to generate pyrolysis oil, carbon black, pyrolysis steel wire, and combustible gas.

1. The waste tyre pyrolysis plant function is converting waste tyres into fuel oil, carbon black, steel wire, and syngas.

2. Capacity from 15ton-30ton capacity,Support customization.

3. Fast installation design & Bulk type design &Container design

4. Environmental friendly, no black smoke and waste water discharged out.

5. Large condensing area ensures a high oil yield.

6. Low operating cost.

7. High Automation. Auto feeding systems and discharging carbon black devices make this recycling machinery much easier to operate.Support PLC system.

8. Certification: CE, ISO, SGS

The characteristics of Continuous pyrolysis :

1) The machine continuously feeds, pyrolysis, and discharges slag 24 hours a day

2) After ignition, the machine can run continuously for a period of 70 days

3) The whole process is anaerobic feeding and anaerobic slag discharge, without any emissions (for environmental protection)

Pyrolysis plant parameter:

|

Name |

Low temperature Continuous Pyrolysis Production Line For Waste Tire |

|||

|

Machine type |

BH-SC15 |

BH-SC20 |

BH-SC25 |

BH-SC30 |

|

Capacity (24h) |

15T |

20T |

25T |

30T |

|

Reactor size |

2000*11000mm |

2400*13200mm |

1200*20000mm |

1400*20000mm |

|

Reactor material |

12Cr1 Mov/Q345R/Q235R |

|||

|

Feed modes |

Automatic feeding by conveyer |

|||

|

Heating modes |

Direct heating(combustible gas/oil recovery) , can be optional |

|||

|

Labor |

2-3 labors for working |

|||

1. Fuel oil (40-45%): Widely used as fuel oil in industries such as steel and iron factories, ceramics or heavy oil generators, cement factories, and boiler heating, etc. Or being refined into non-standard diesel for use in trucks, tractors, etc.

2. Carbon black(30%): Be pressed into pellets for use in industrial heating

3. Steel wires(10%): Sold or reprocessed.

4. Combustible gas(10%-15%): Can be recycled and used during production as fuel.

Export shipment:

Our Advantages:

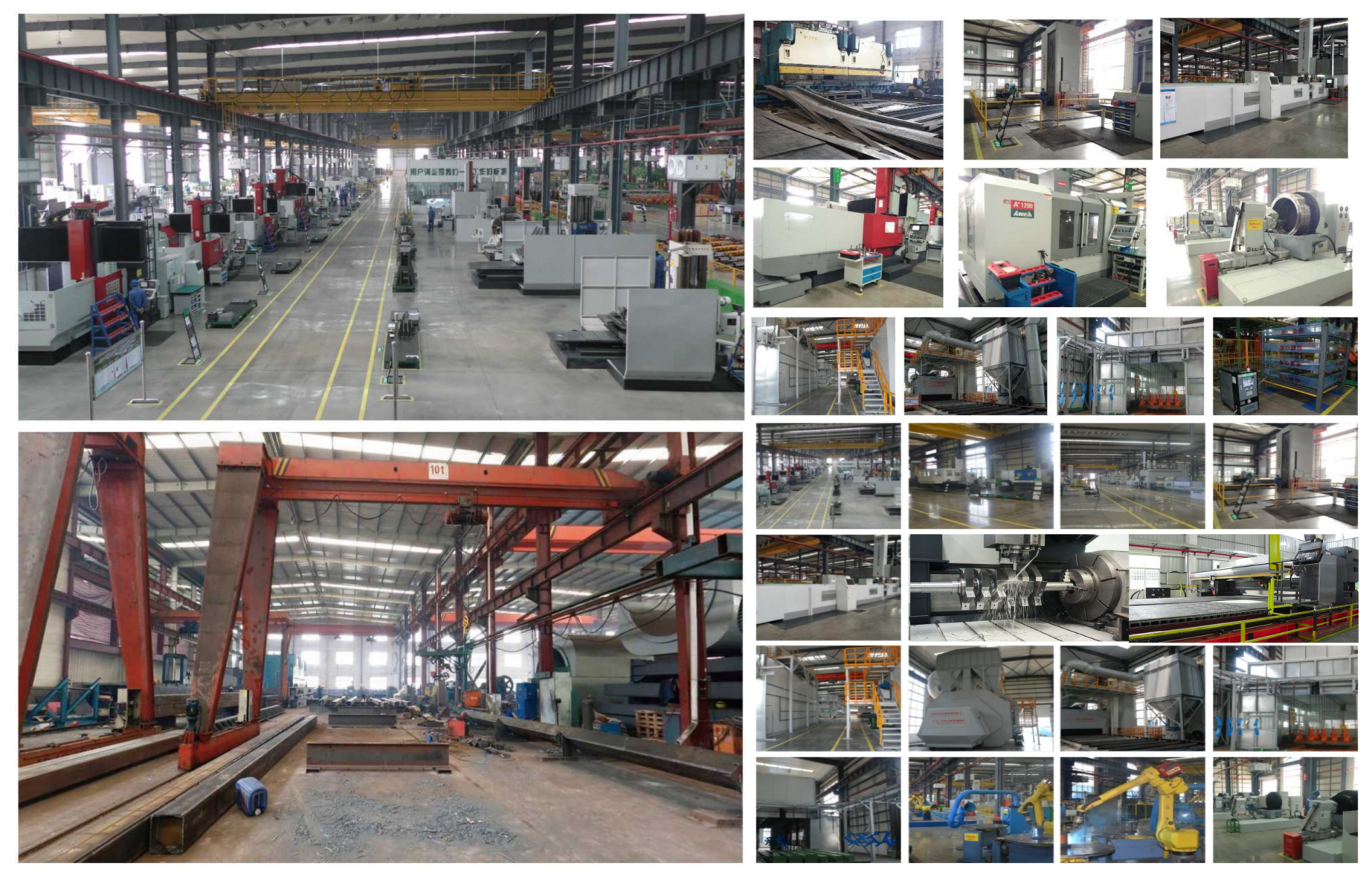

Our company mainly produces fully automatic waste tire shredding and pyrolysising production lines, waste rubber pyrolysis equipment, waste plastic pyrolysis machine, and oil sludge pyrolysis machine.At the same time, our company integrates front-end processing, mid-range cracking machine, and back-end carbon black grinding and granulation,The entire production chain has achieved low energy consumption、fully intelligent、zero emission、zero pollution and zero residue,Realizing the reuse of green and environmentally friendly resources by recycling and pyrolysising waste tires.

Keywords: Waste Tire Pyrolysis Plant | Recycling machine | Carbon Black Processing Machine

Related Products

Related Messages

Qingdao Longyuan Baihong Machinery Equipment Co., Ltd.

Mob: +86 15854201728(Helen)

E-mail: info@qdlybh.com

Add: 513 Guangzhou North Road, Jiaozhou City, Qingdao,Shandong Province,China

Customer Message

Copyright © 2023 Longyuan Baihong SEO Business license